-

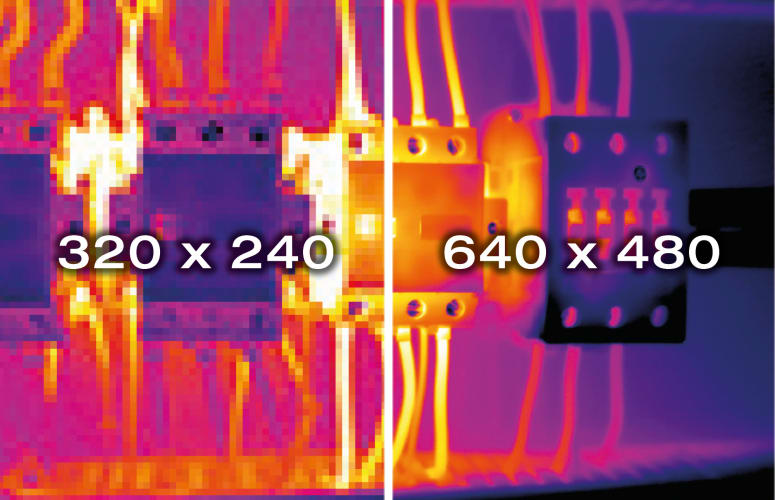

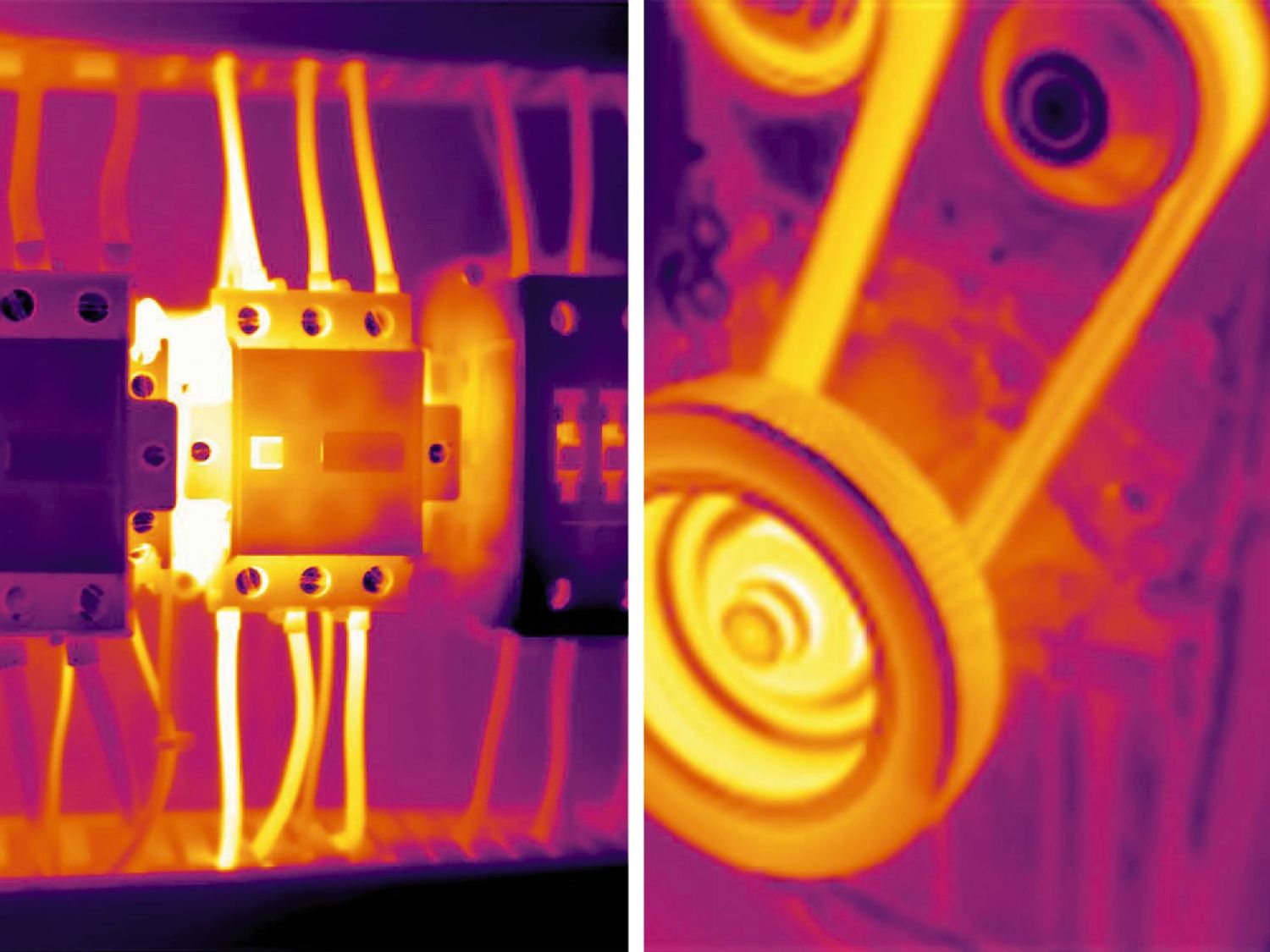

Best image quality: IR resolution of 320 x 240 pixels (with SuperResolution 640 x 480 pixels); NETD < 40 mk

-

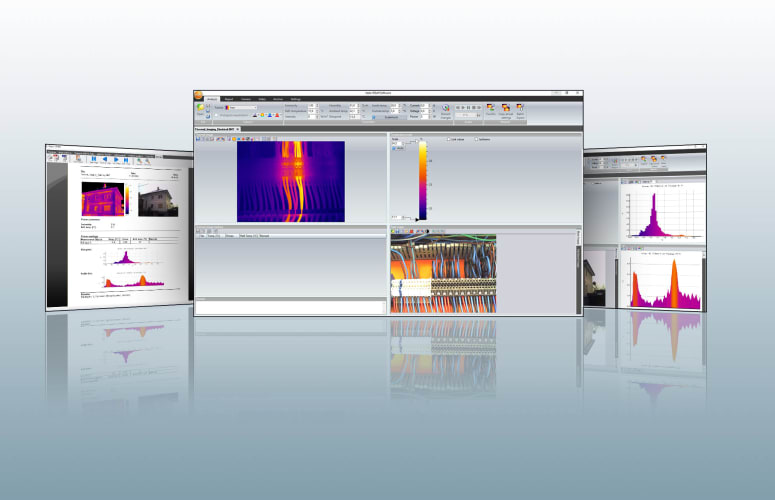

Practical: testo SiteRecognition intelligent image management, testo ScaleAssist automatic contrast adjustment, intuitive professional software testo IRSoft for analyses and documentation

-

Full control: Manual focus and interchangeable lenses

-

In the kit: testo 883 thermal imager including standard lens 30° x 23°, telephoto lens 12° x 9°, spare battery, battery-charging station and case

-

Standards EU-/EG-guidelines

RED: 2014/53/EU; EMC: 2014/30/EU; WEEE: 2012/19/EU; RoHS: 2011/65/EU + 2015/863; REACH: 1907/2006

General technical data Product colour

Black

Display ligthing

bright / normal / dark

Display type

capacitive touch display

Infrared image output Field of view

30° x 23° (Standard lens), 12° x 9° (Telephoto lens, optional)

Focus

manual

Minimum focus distance

< 0.1 m (Standard lens)

Geometric resolution (IFOV)

1.7 mrad (standard lens), 0.7 mrad (telephoto lens)

Image refresh rate

27 Hz

Infrared resolution

320 x 240 pixel

SuperResolution (IFOV)

1.1 mrad (Standard lens), 0.4 mrad (Telephoto lens)

SuperResolution (Pixel)

640 x 480 pixels

Thermal sensitivity

˂ 40 mK

Spectral range

7.5 to 14 µm

* Inside the EU, outside 9 Hz

Image output visual Minimum focus distance

< 0.4 m

Image size

5 MP

Image presentation Colours

iron, rainbow, rainbow HC, cold-hot, blue-red, grey, inverted grey, sepia, Testo, iron HAT, humidity palette

Digital zoom

2x; 4x

Display option

IR image / real image

Display type

8.9 cm (3.5") TFT, QVGA (320 x 240 pixels)

Measurement Accuracy

±2 °C, ±2 % of m.v.; (greater value applies)

Emissivity

0.01 to 1

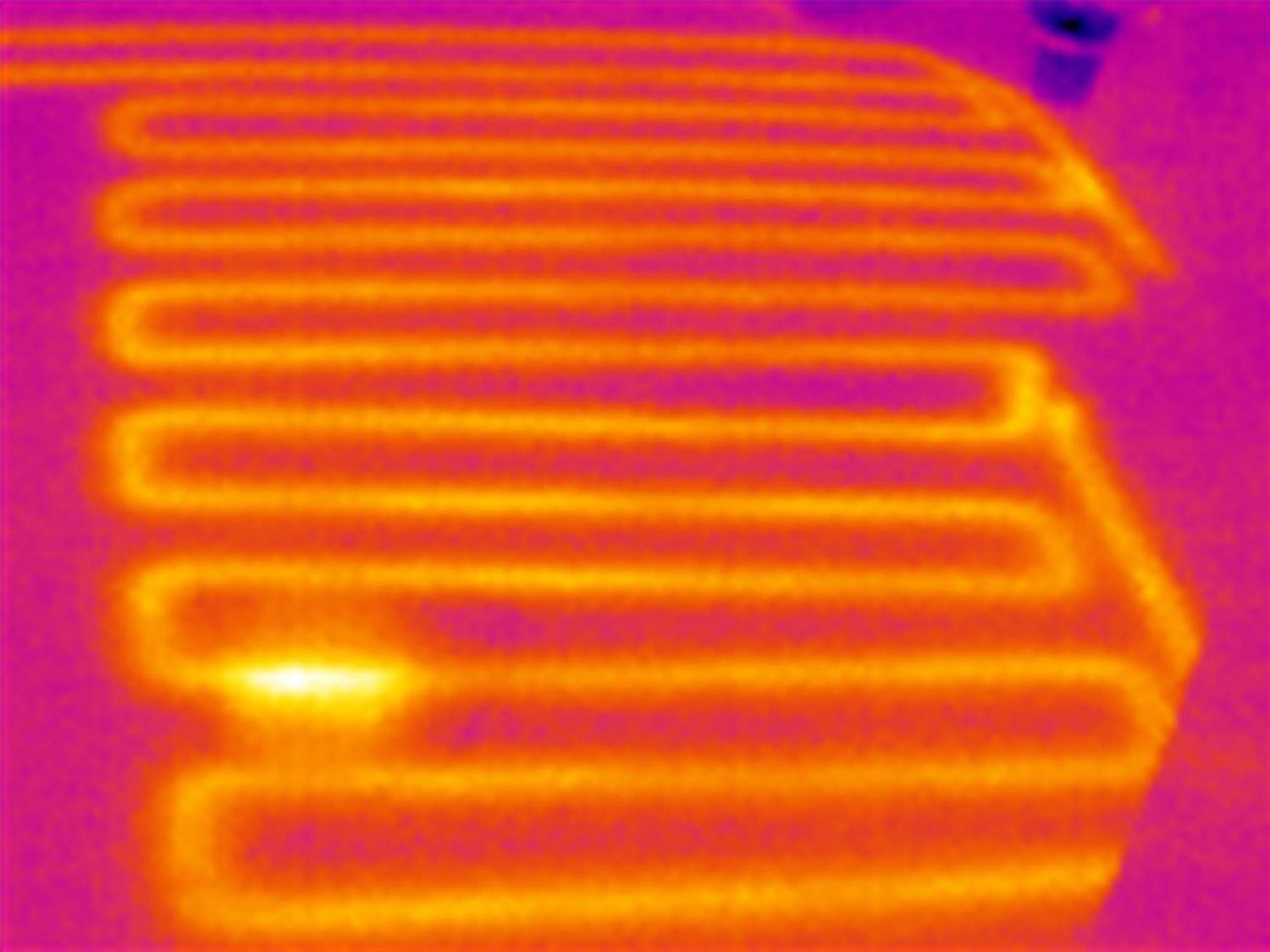

Measuring range

-30 to +650°C

Reflected temperature

manual

testo ε-Assist

Included

Measuring function Analysis function

Up to 5 selectable individual measuring points, hot/cold spot detection, Delta T, area measurement (min/max on area), alarms, isotherm

Solar mode – manual

Input of solar radiation value

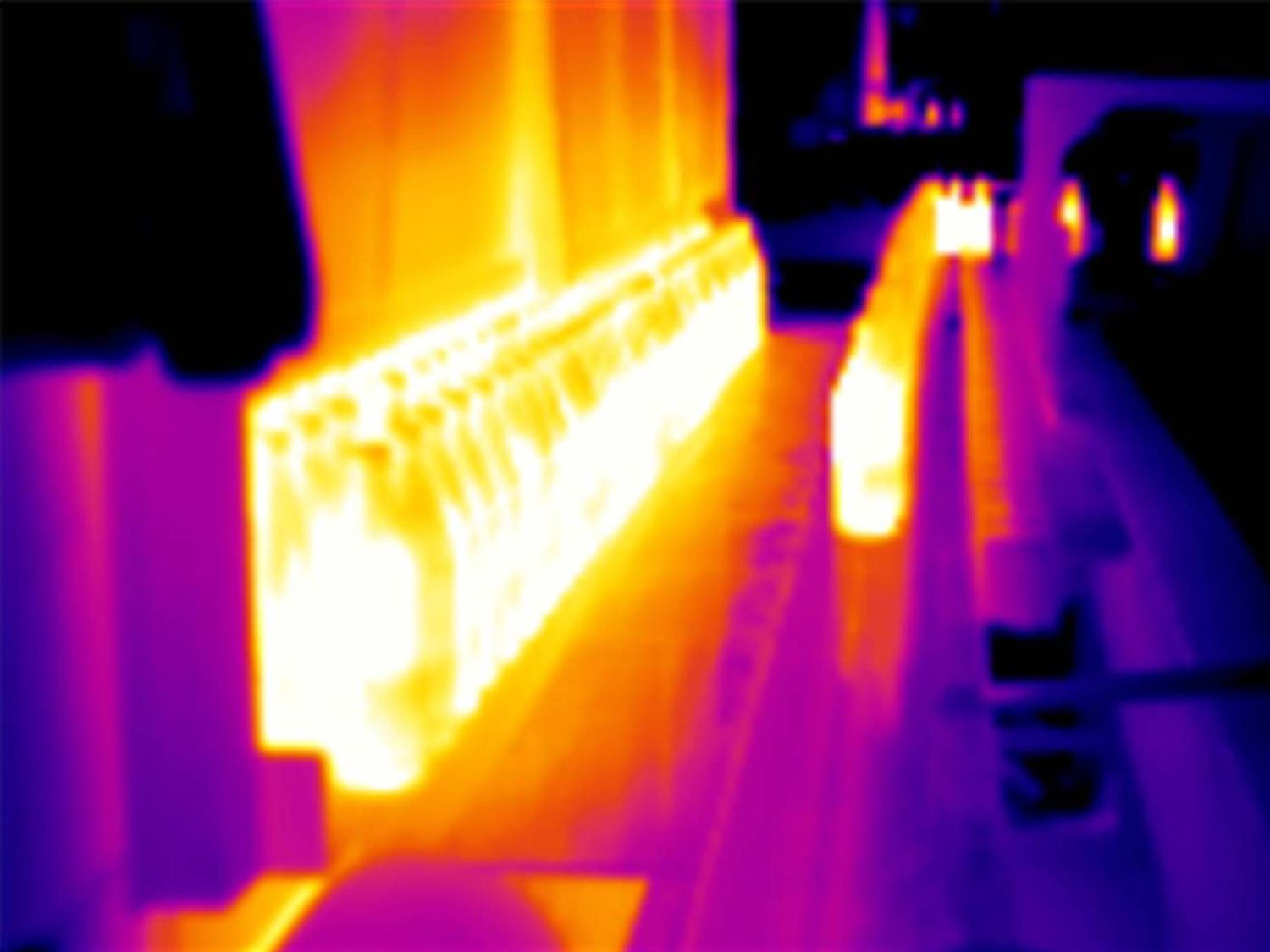

Electrical mode - manual

Input of current, voltage or power

Humidity mode - manual

Included

Humidity measurement with humidity measuring instrument

Automatic measurement value transfer of thermohygrometer testo 605i via Bluetooth (instrument must be ordered separately)

IFOV warner

Included

testo ScaleAssist

Included

Electrical measurement with clamp meter

Automatic measurement value transfer of clamp meter testo 770-3 via Bluetooth (instrument must be ordedered separately)

* An overview of radio authorizations in the different countries can be found in the download section of the respective product page (www.testo.com)

Imager equipment Voice recording

Included

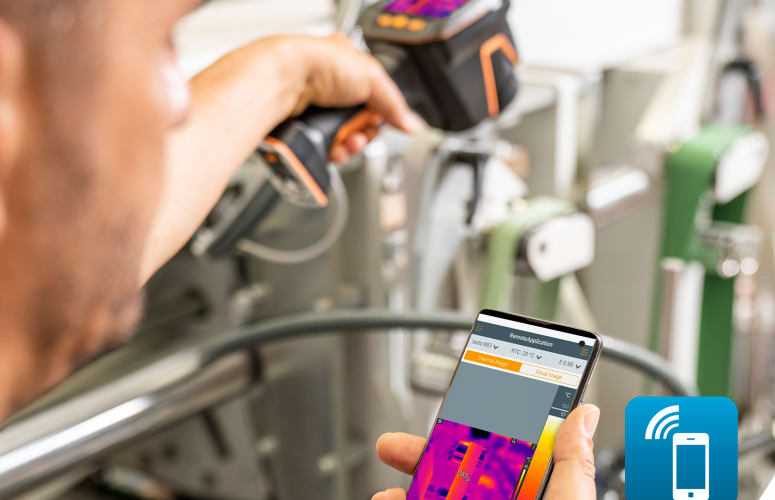

Video streaming

via wireless LAN with testo Thermography App; via USB

Standard lens

30° x 23°

SiteRecognition

Included

Laser

Laser marker

JPEG storage

Included

Full screen mode

Included

Digital camera

Included

Interface

USB 2.0; USB-C

WLAN Connectivity

Communication with the testo Thermography App/ wireless module BT/WLAN*

Bluetooth

Headset for voice annotations, transfer of readings from testo 605i thermohygrometer, testo 770-3 clamp meter (optional)**

* An overview of radio authorizations in the different countries can be found in the download section of the respective product page (www.testo.com)

** excepting USA, China

Laser: excepting USA, China and Japan

Voice recording : An overview of radio authorizations in the different countries can be found in the download section of the respective product page (www.testo.com)Imager storage File format image

.bmt; .jpg; export option in .bmp; .jpg; .png; .csv; .xls

Storage device

Internal Memory (2.8 GB)

Power supply Battery type

Fast-charging, Li-ion battery can be changed on-site

Charging options

In instrument / charger (optional)

Mains operation

yes

Operating time

≥ 5 h

Ambient Condition Air humidity

20 to 80 %RH non-condensing

Housing protection class

IP54

Vibration

2G

Storage temperature

-30 to +60 °C

Operating temperature

-15 to +50 °C

Physical specification Product-/housing material

PC - ABS

Tripod mounting

1/4" - 20UNC; carrying strap

Weight

824 g

Dimensions

171 x 95 x 236 mm

PC software System requirements

Windows® 11 ; Windows® 10; Windows® 8; Windows® 7

-

General technical data Weight

119 g

Dimensions

20 x 24 x 140 mm (LxWxH)

Product colour

Black

-

General technical data Weight

385 g

Dimensions

80 x 90 x 75 mm (LxWxH)

Cable length

1 m

Product colour

black/orange