-

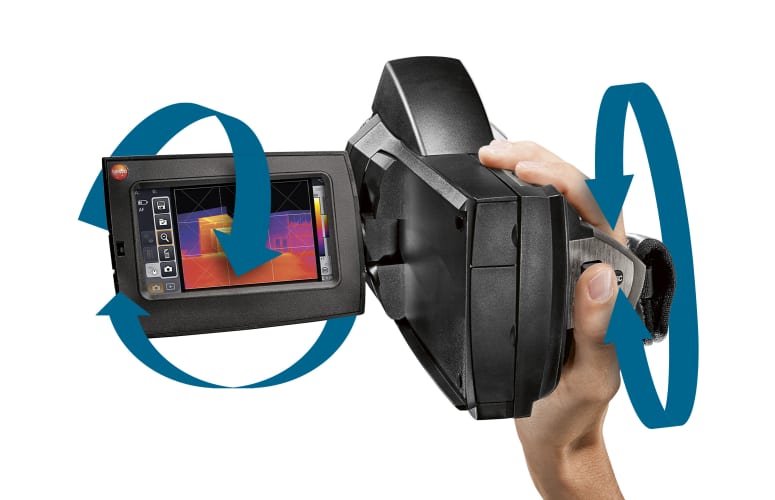

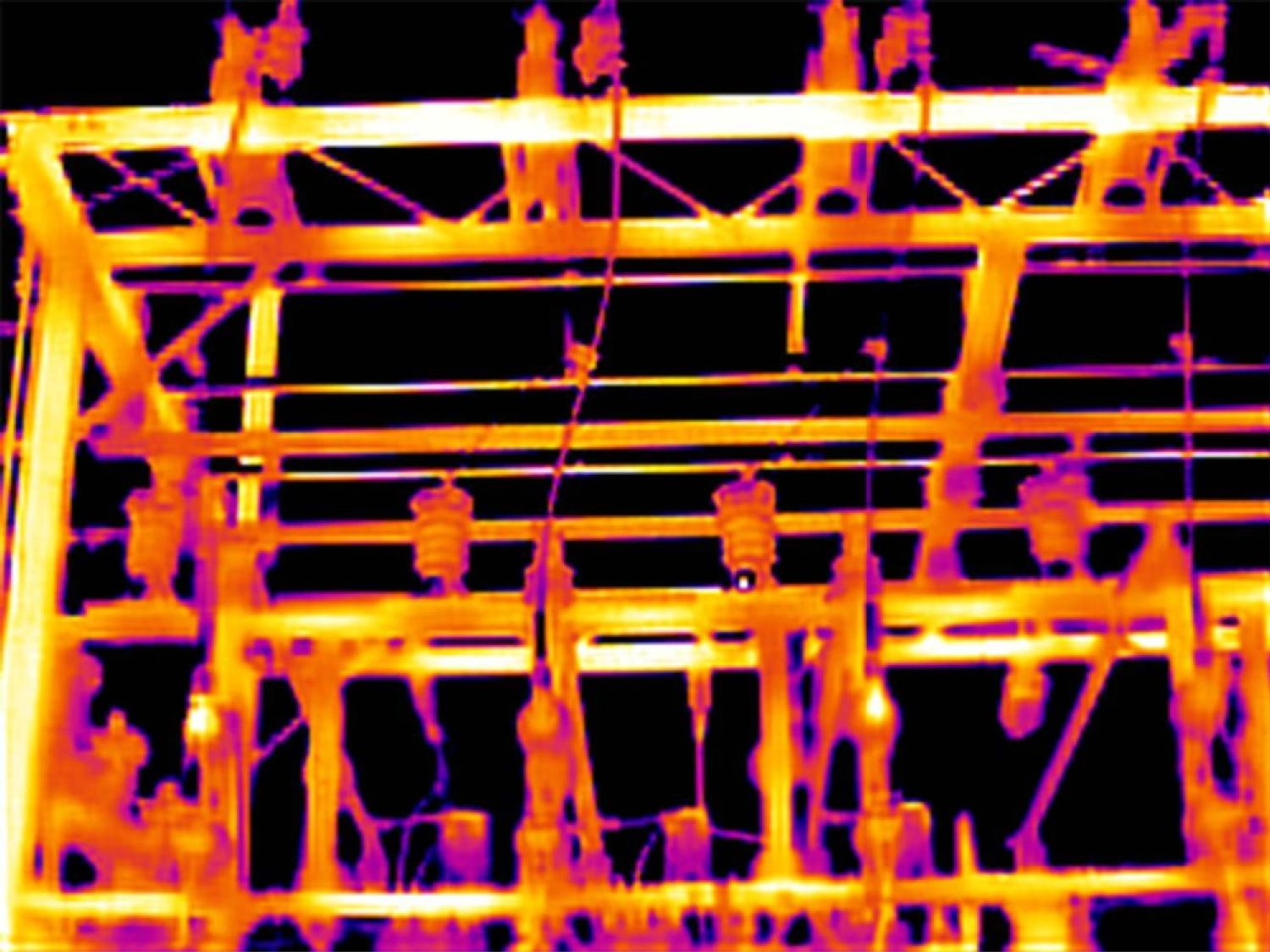

testo 890 professional thermal imager: resolution 640 × 480 pixels, upgradable to 1280 × 960 pixels with SuperResolution technology, thermal sensitivity < 40 mK

-

Choice of lens between standard, 25° and telephoto lens – you are free to choose one lens

-

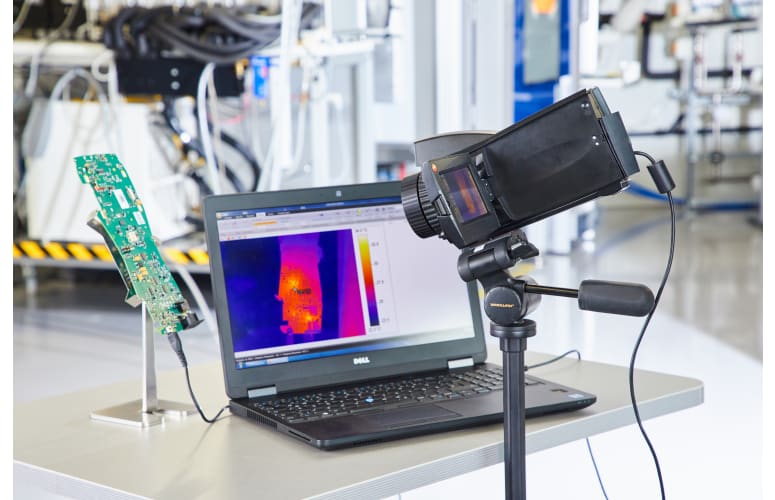

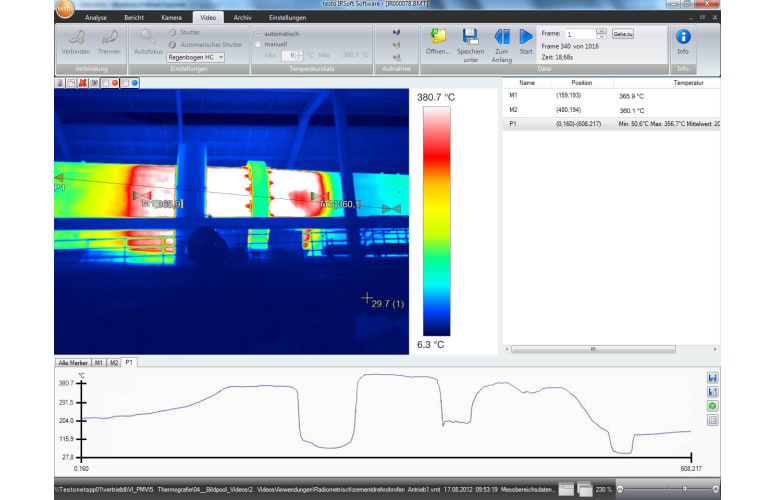

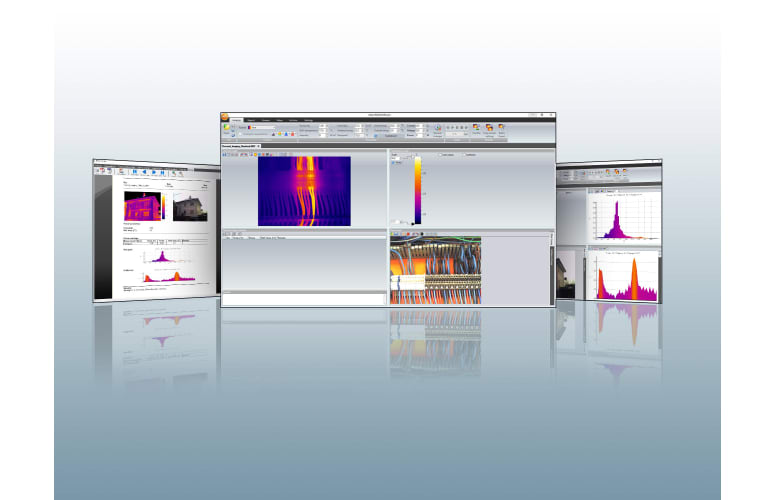

Sequence capturing in the instrument a possible option, humidity calculation, SiteRecognition, panorama image assistant, JPEG storage function and other practical features

-

Integrated digital camera, optionally exchangeable lenses, many more features, large scope of delivery including transport case, memory card, professional software, etc.

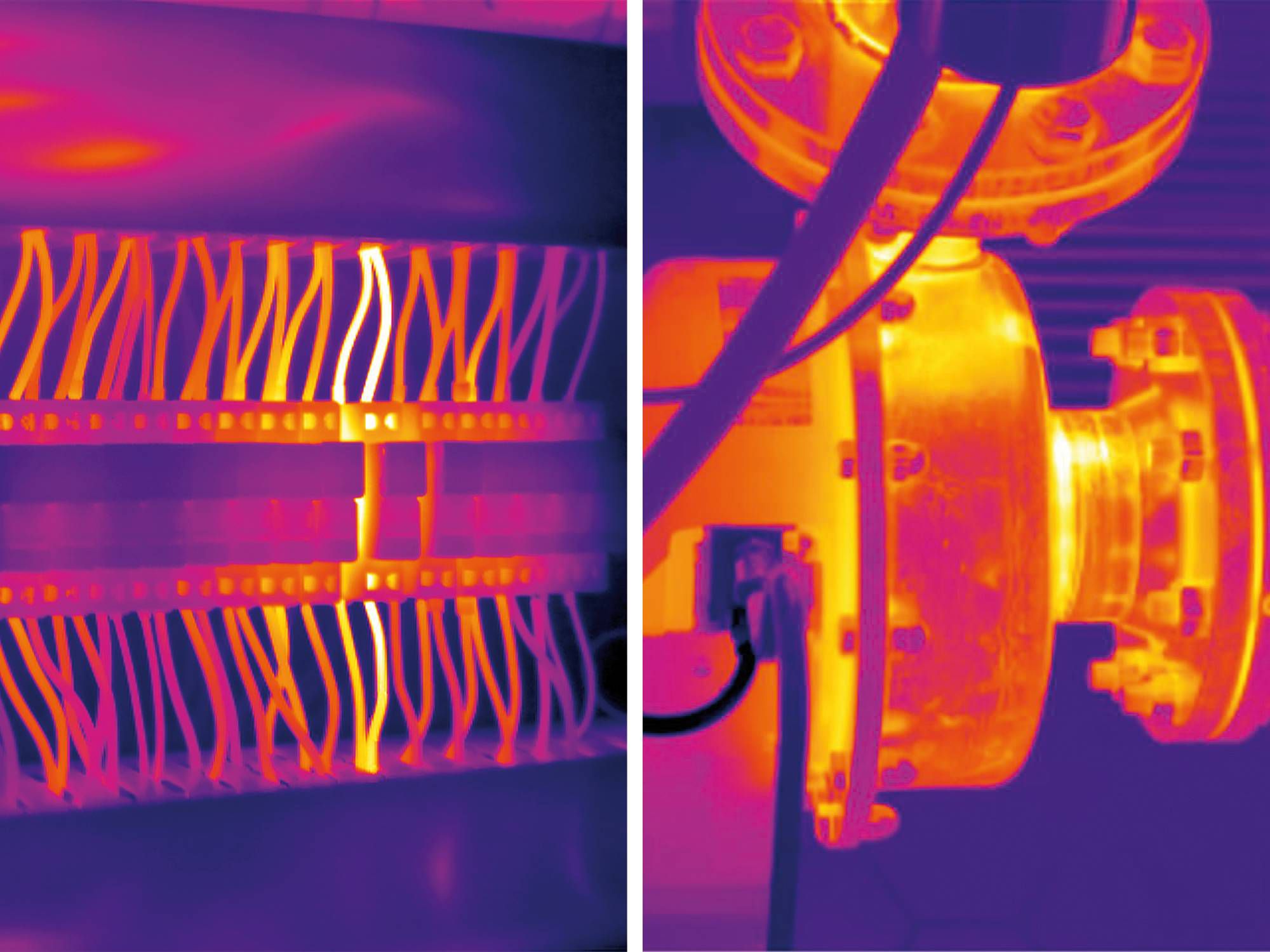

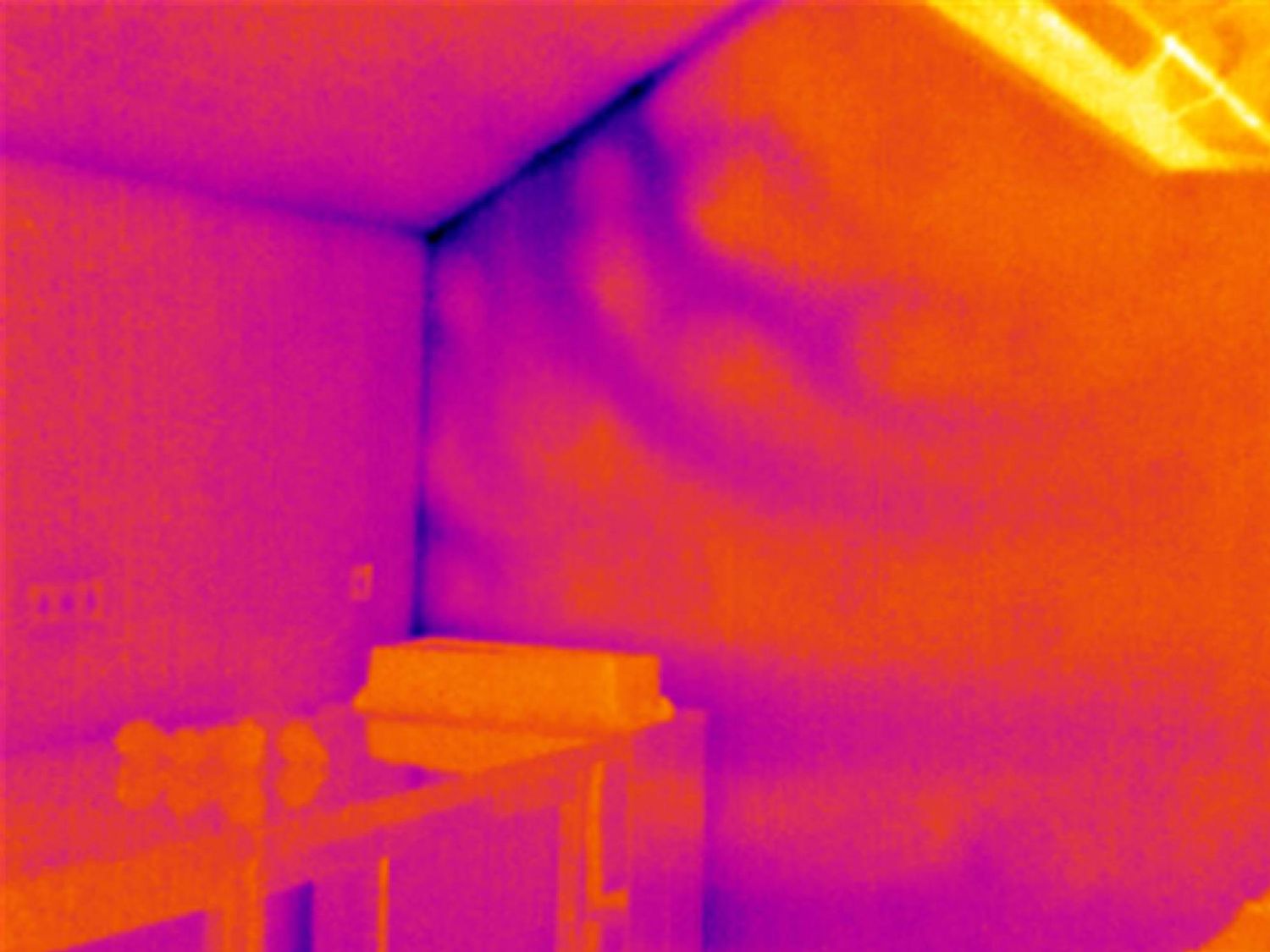

The testo 890 thermal imager means you are ideally equipped both for professional industrial thermography and for building thermography: e.g. for inspecting voltage systems, high-temperature measurement, circuit board analysis, control of solar plants, complete building shell thermography and building thermography for energy consultancy.