With Testo's SuperResolution technology, you can capture extremely high-resolution infrared images (up to megapixel quality) with your Testo thermal imagers. The high-definition SuperResolution thermal images improve the usable geometric resolution of the thermal image by a factor of 1.6 – with four times as many measuring values.

Super-Resolution Technologies for Thermography

Revolutionary technology – SuperResolution

SuperResolution technology is always sought when you need the greatest possible detail in the images for your professional thermographic analysis. The thermal imager's infrared images have a considerably higher resolution and greater detail. The important thing is that: SuperResolution technology always records genuine temperature measuring values – there are no artificial intermediate values projected! This means that SuperResolution technology offers the possibility - without using larger, more expensive detectors - of recording more temperature measuring values with the thermal imager.

Thermal images now in megapixel quality

With SuperResolution technology, you improve the infrared quality of the high-end testo 890 thermal imager by one class in no time at all: four times as many measuring values and a geometric resolution of the infrared image resolution that is improved by a factor of 1.6 which means you get high-resolution thermal images (1280 x 960 pixels) in megapixel quality! Together with the outstanding thermal sensitivity of < 40 mK, thermographic measurement with the testo 890 and SuperResolution gives you a thermal image which is accurate in every detail and therefore even greater reliability in terms of measurement.

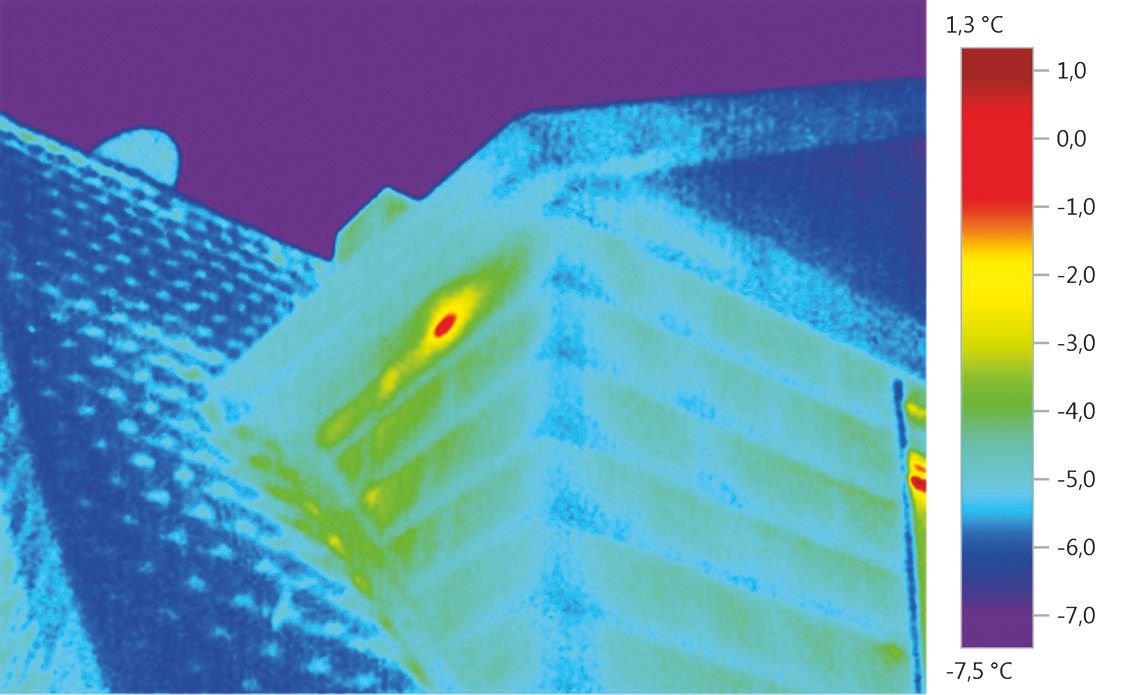

SuperResolution in building thermography

In building thermography, SuperResolution technology is ideally suited for fast and easy detection of building damage. In addition, energy losses in the heating or air conditioning of buildings can be analysed using high-resolution thermal images. The high level of detail in the image makes inadequate insulation, resulting heat losses or construction defects clearly visible. Leakages can also be displayed precisely in the thermal image using SuperResolution technology.

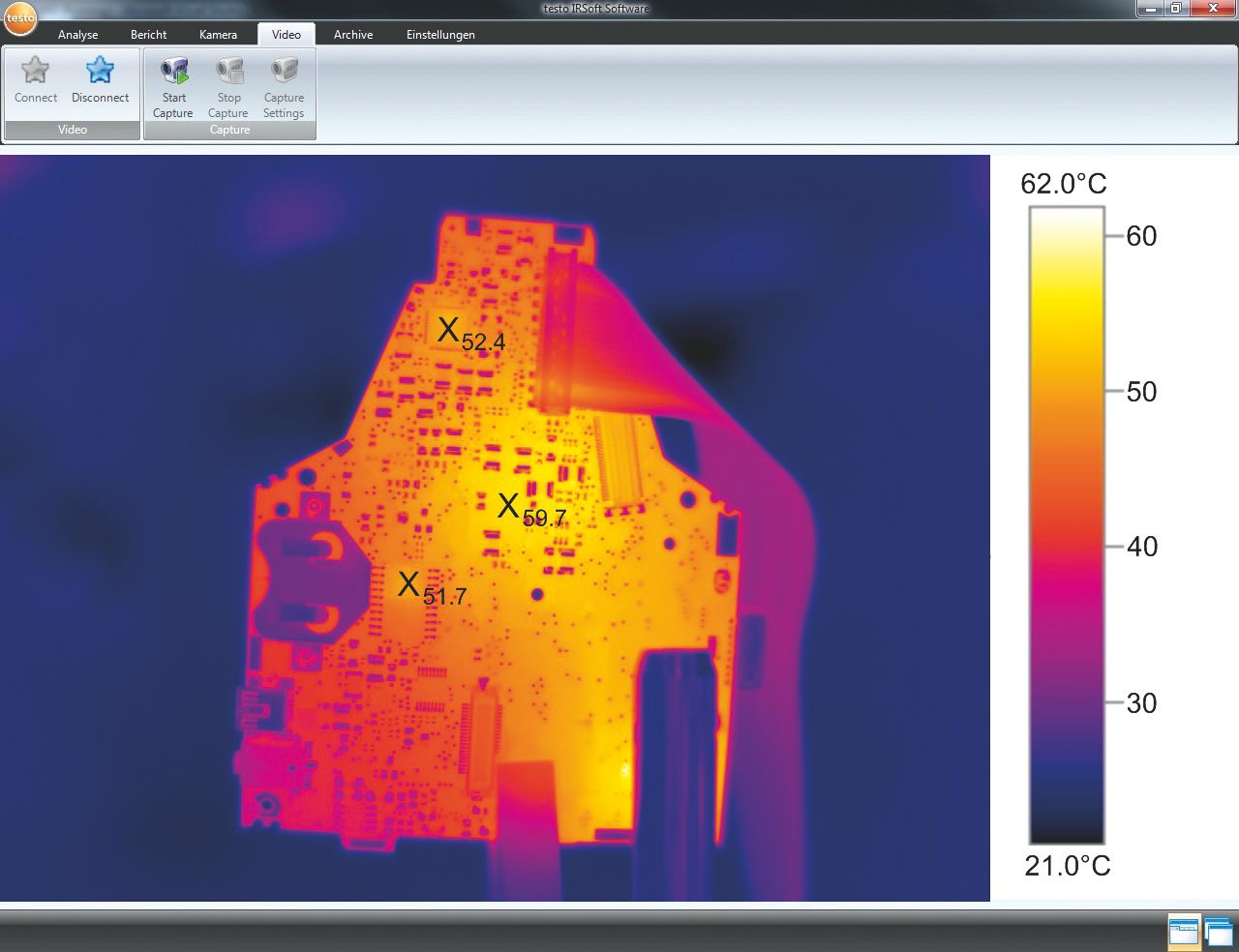

SuperResolution in industrial thermography

The geometric resolution of the thermal image plays an important role, particularly in the research & development field. This has been improved by a factor of 1.6 thanks to SuperResolution technology. This means the size of the smallest measurable object is also reduced, which enables the measurement of the smallest structures. So, the tiniest structures down to 0.07 mm can be thermographed using the testo 890 and SuperResolution technology in high resolution. SuperResolution is therefore always particularly important when very small objects need to be thermographed (e.g. a circuit board), or when you need to explore the smallest details in the thermal image after measurement using the Testo analysis software on the PC. At the same time, more details can be identified with images captured from a great distance.

SuperResolution technology also plays an important role in industrial maintenance – above all in the detailed early detection of imminent damage in production-related plant components. In case of mechanical components too, the detection of thermal irregularities (e.g. due to friction or incorrect adjustment) can indicate an elevated level of stress.