-

Increased measurement range for unlimited measurements even when gas concentrations are higher

-

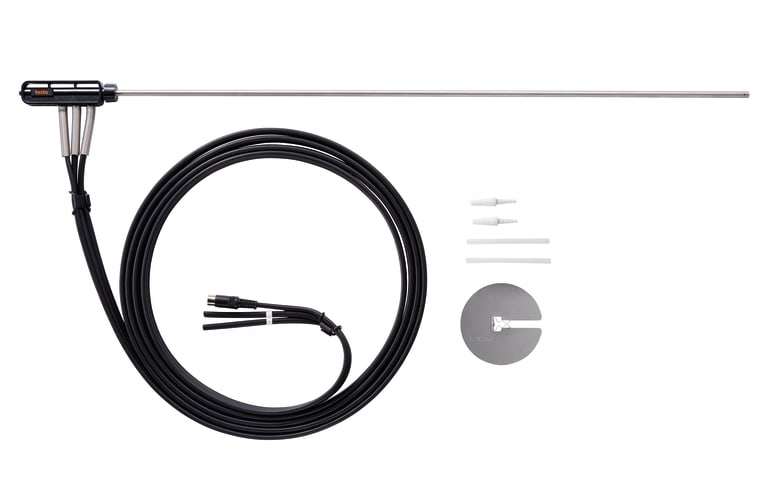

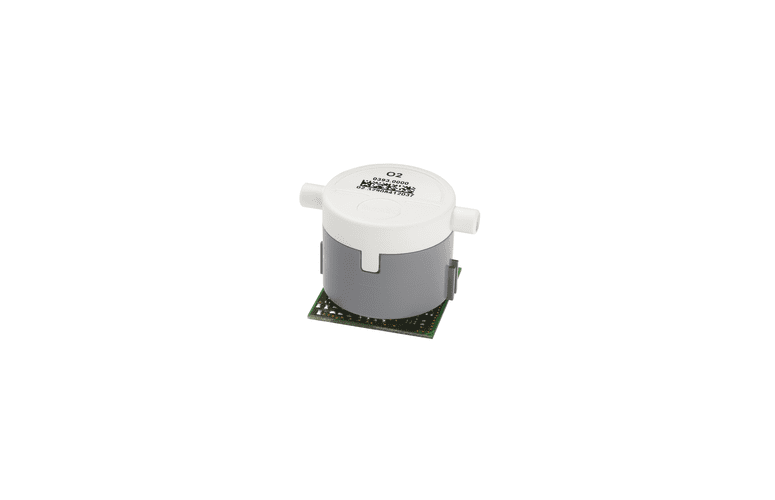

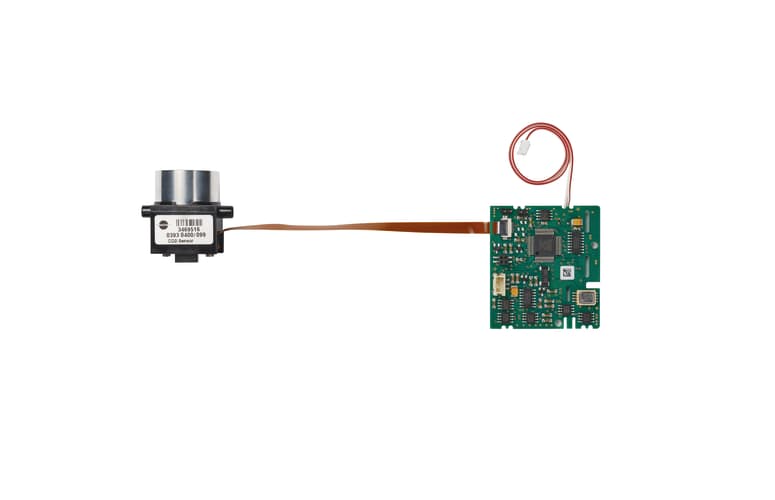

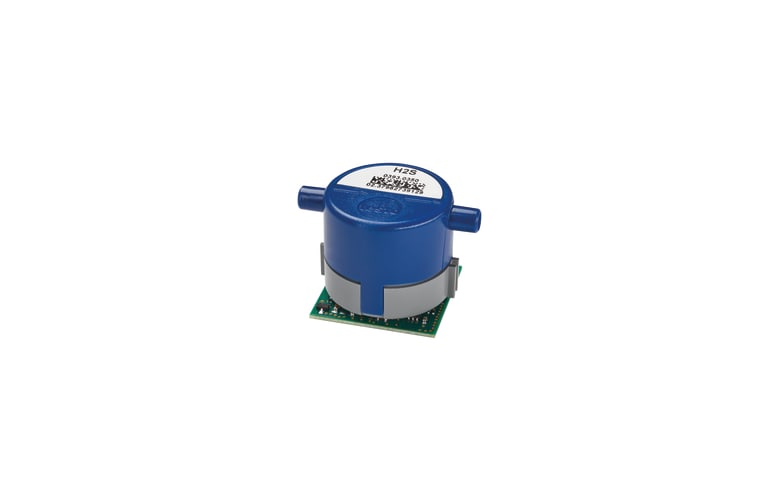

Easy-to-change gas sensors and easy access to wearing parts

-

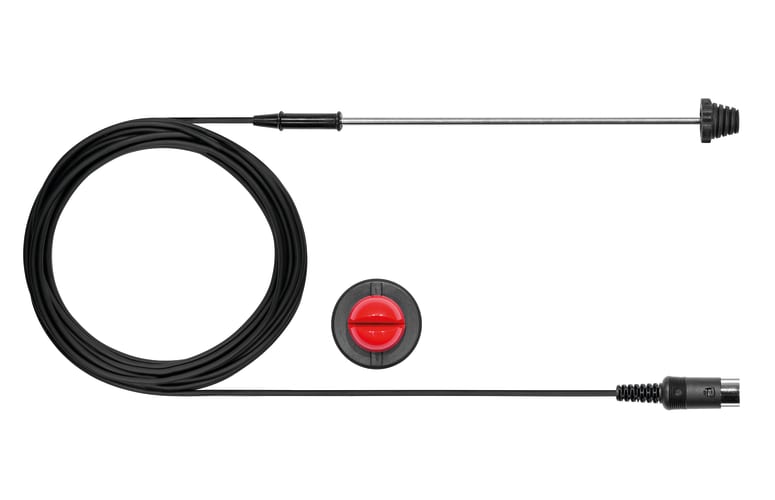

Sealed housing with built-in impact protection for use in harsh conditions

-

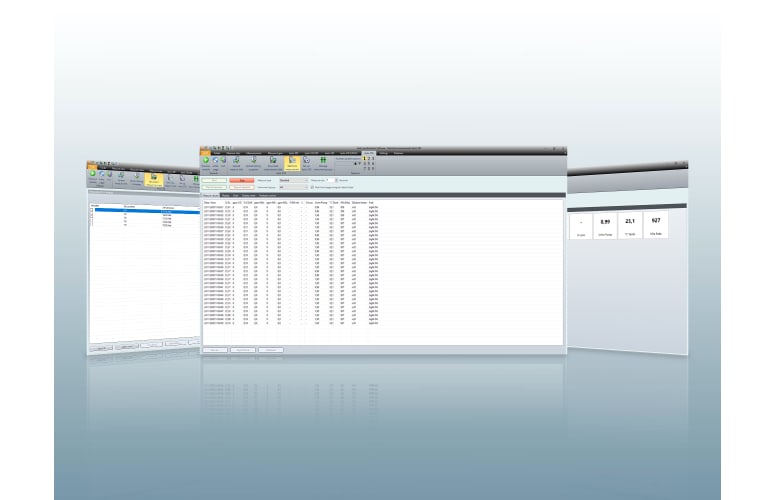

Easy operation of the analyzer unit via Control Unit or easyEmission software (both products available separately)

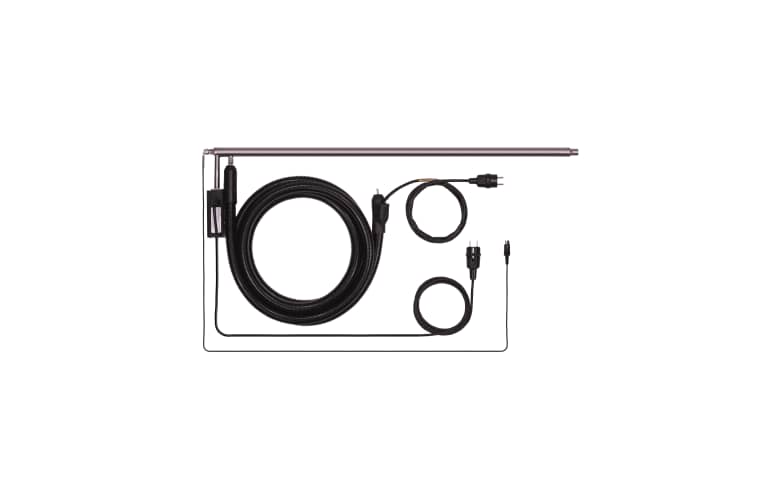

The testo 350 is a rugged, easy-to-use exhaust gas analyzer designed to meet the highest demands when it comes to carrying out precise industrial emission measurements and providing proper data administration. The Analysis Box can be operated with up to 6 gas sensors, 5 of which are optional. This allows you to select freely from sensors for CO, NO, NO2, SO2, H2S, CxHy and CO2.