Service measurement on industrial engines

Flue gas analysis instruments are one of the items of equipment that are used on a daily basis by service engineers to achieve optimum tuning of engines. Flue gas measurement is used on industrial engines when they are commissioned, at regular maintenance intervals or for troubleshooting when they are running in an unstable way. The background to flue gas measurement is tuning the engine to the optimum operating parameters while complying with the limit value regulations in force. Maintenance work that is carried out regularly makes an important contribution to avoiding downtimes over the long term, to ensuring the quality of the system and thus a high level of efficiency and to having a significant influence on emission levels.

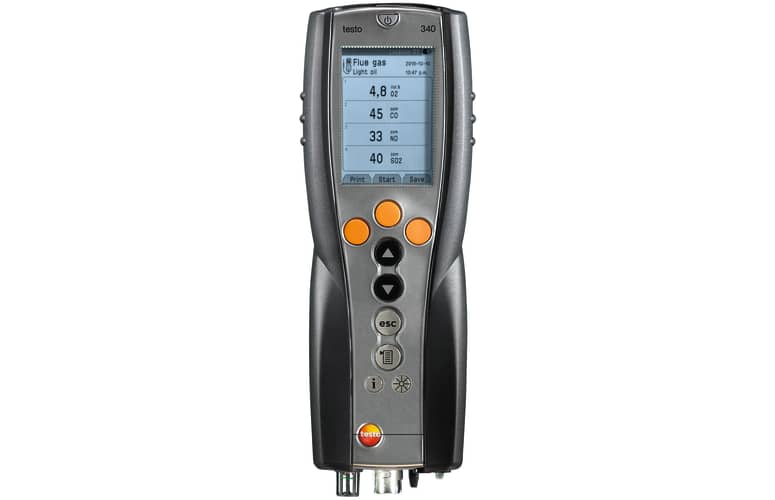

Advantages of the testo 340

Separate NO and NO2 measurement

- The real NOx value is measured with the NO and NO2 sensor combination. In gas engines, the NO2 component of the NOx value can fluctuate greatly, so the separate measurement of each of the gases is necessary for correct NOx values.

Measurements even at high CO concentrations

- At unexpectedly high concentrations (up to 50,000 ppm), the automatic dilution of the sensor with fresh air allows measurements even when the engine conditions are not defined, without negatively affecting the service life of the sensor.

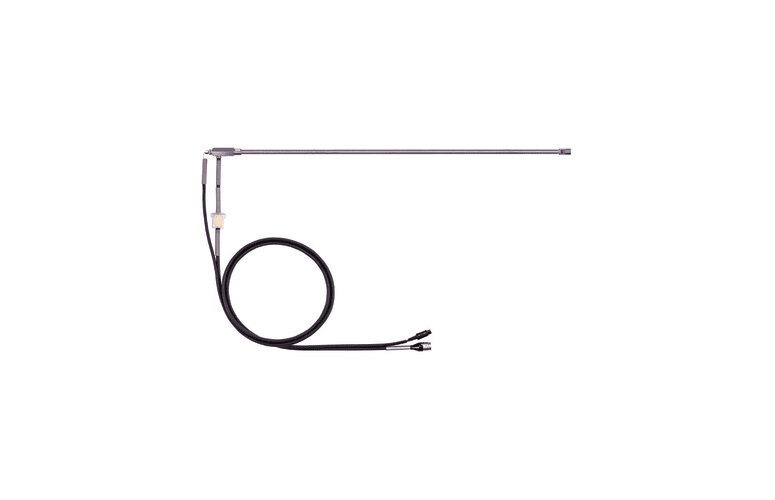

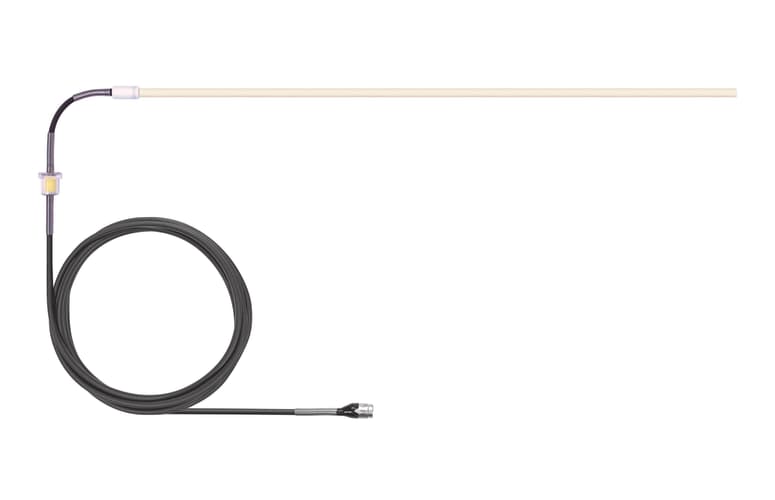

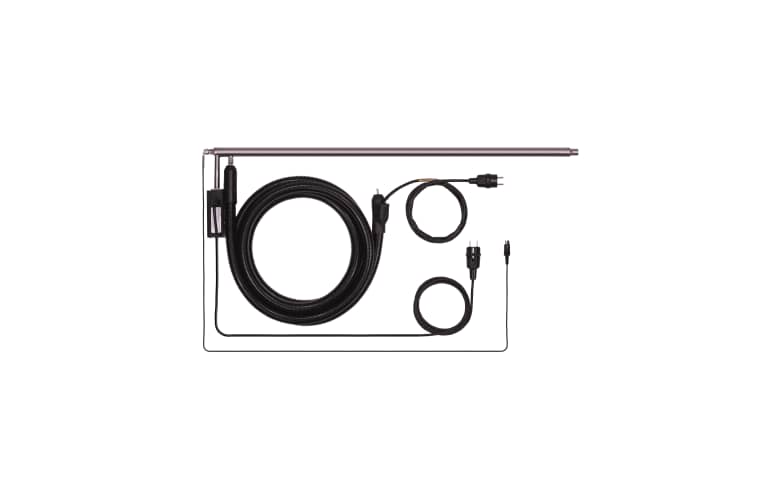

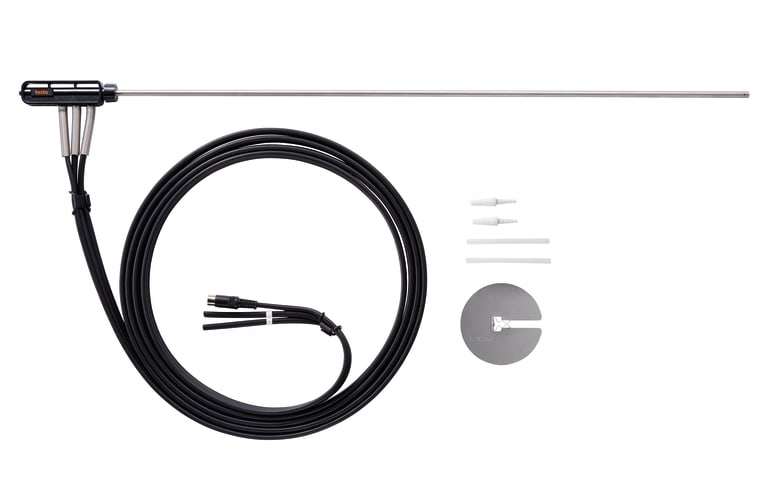

Special flue gas probes for industrial engines as an accessory

- These probes are highly heat-resistant and specially designed to compensate for different pressure conditions, e. g. for measurements before and after the catalytic converter.

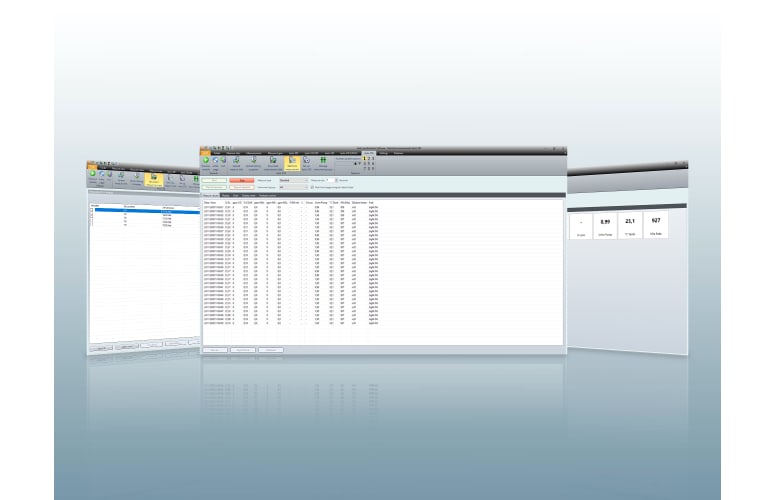

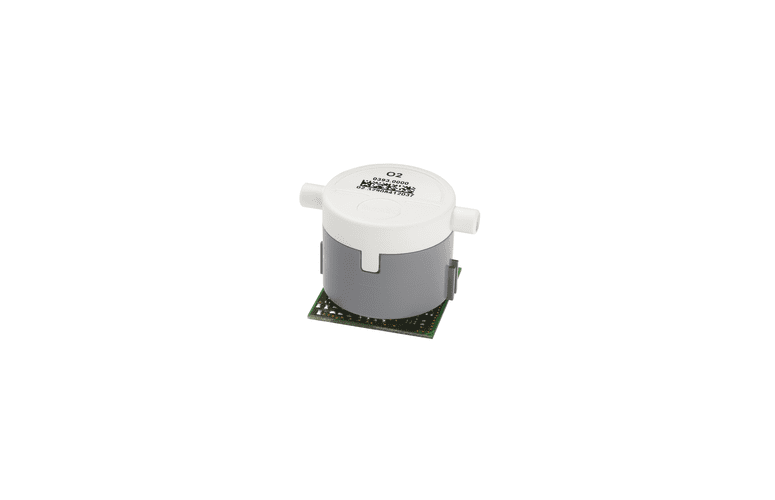

Engine-specific parameters

- The most important parameters for industrial engines such as O2, CO, NO, NO2, NOx and Lambda can be displayed simultaneously.