-

On-site digital creation of reports with the testo 330i App

-

Operation independent of measuring location – readings are always available when you need

-

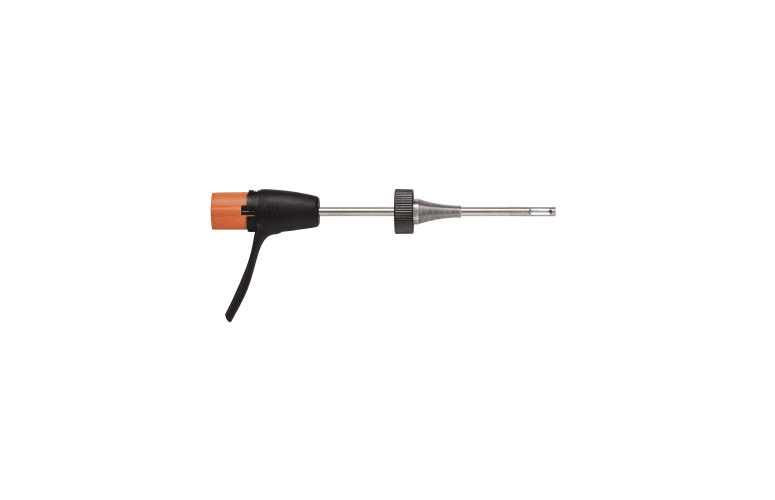

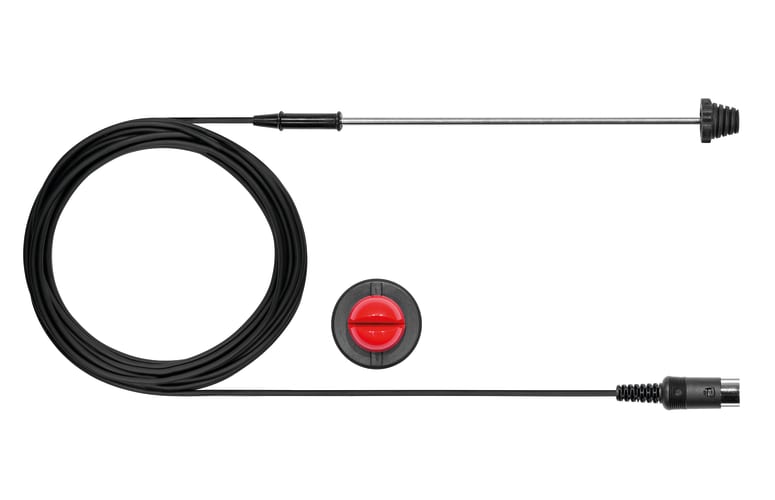

testoFix probe holder (optional) – holds the probe in the centre of flow at all times

-

Particularly robust, completely enclosed plastic housing

Proven technology meets revolutionary operation. The testo 330i flue gas analyzer was specifically developed to help you to overcome all the obstacles you meet when servicing and commissioning heating systems.