-

Unlimited operating time

-

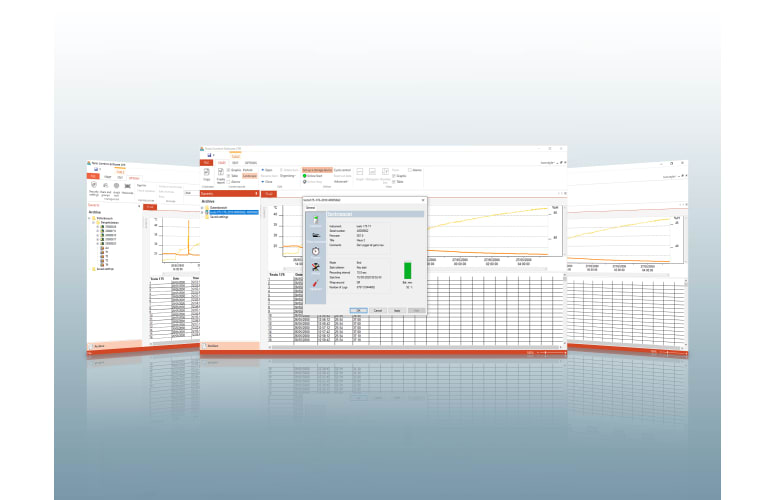

All in one data logger: PDF measurement data, configuration file and instruction manual

-

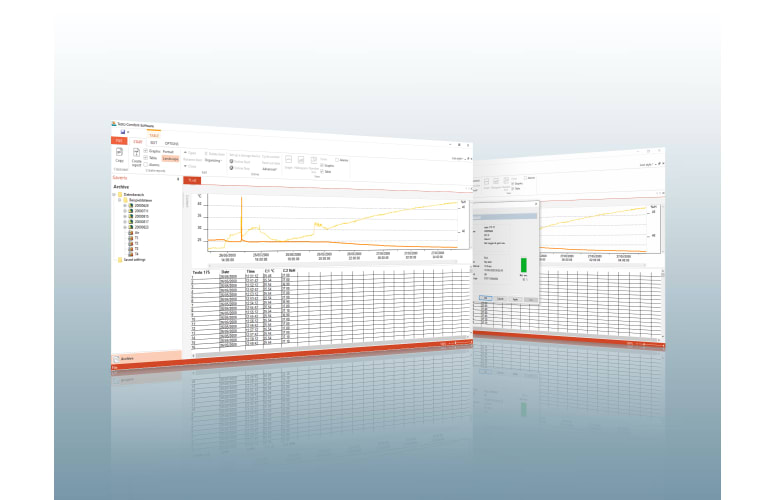

Immediate creation of a PDF report directly after connection to a computer

-

Transport monitoring in compliance with GxP, 21 CFR Part 11 and HACCP

With the data logger testo 184 G1 for shock, humidity and temperature, you can now monitor the transport of sensitive products such as electronics, art, pharmaceuticals or foods safely and conveniently. Thanks to a start and stop button, the data logger guarantees easiest data recording operation. At their destination, a glance at the display or the LEDs tells you whether the configured limit values have been adhered to during transport.