The testo 176 T4 temperature data logger can tell you at a glance if the temperature of the room or facility is within the prescribed thresholds. It can measure the temperature at up to four different sites simultaneously and has a super size memory that can save up to 2 000 000 readings. This gives you the freedom to read out the logger data at longer intervals, even when measuring cycles are shorter.

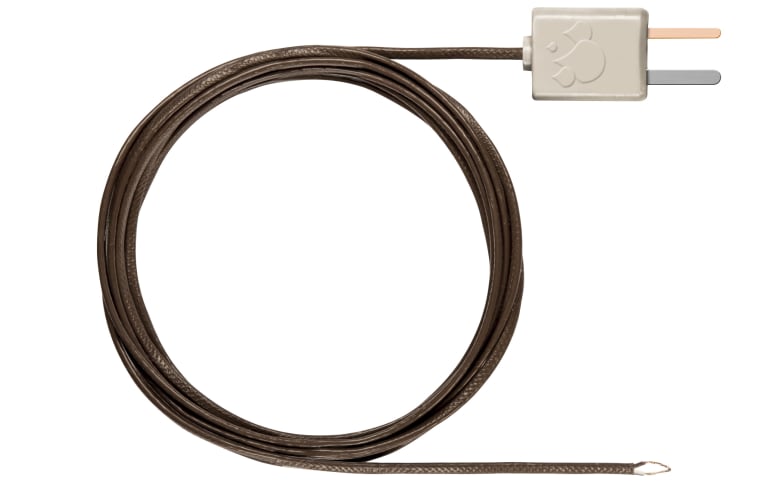

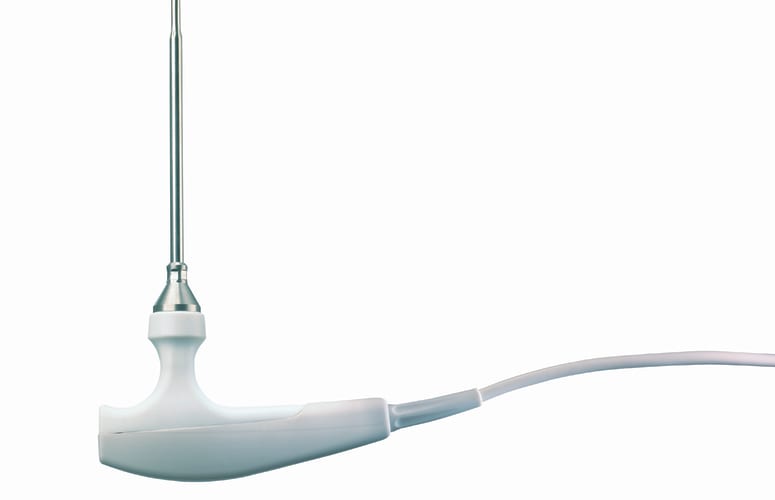

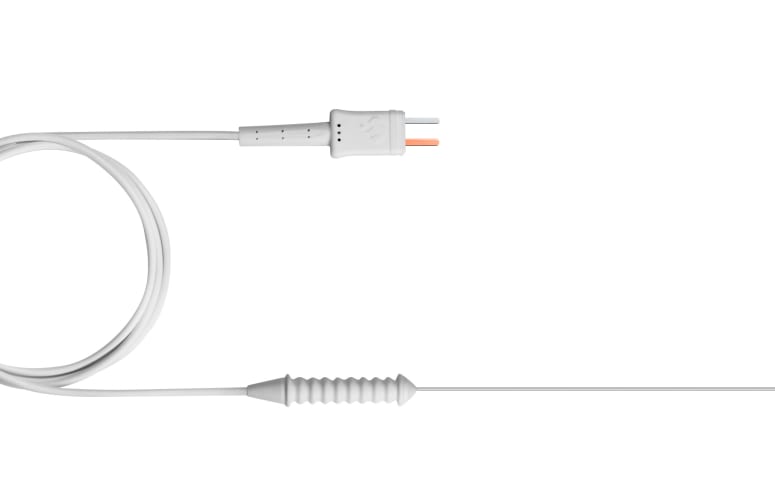

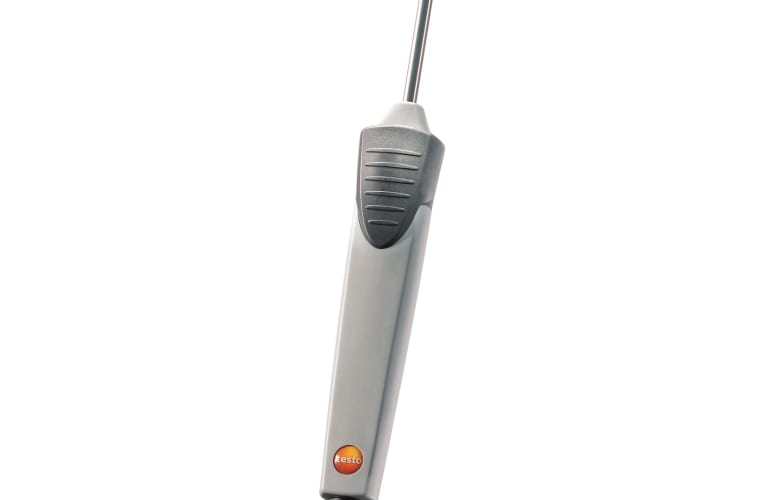

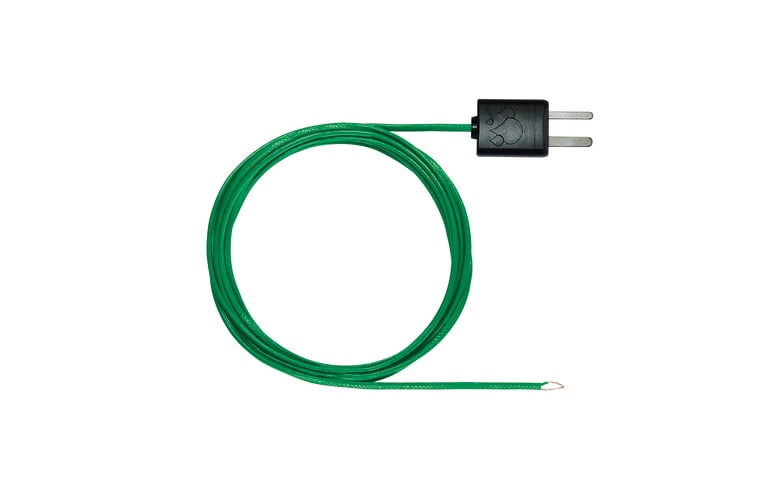

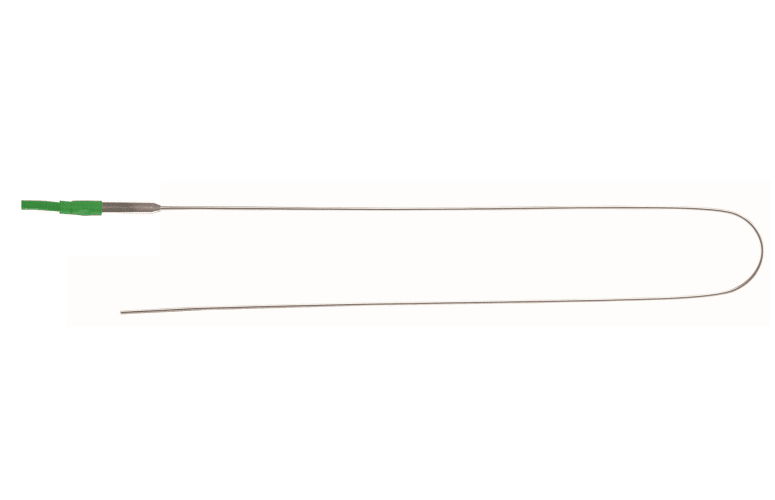

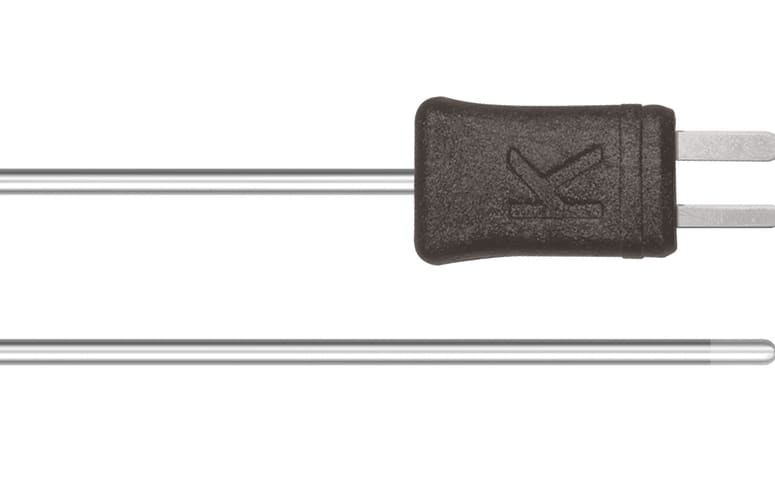

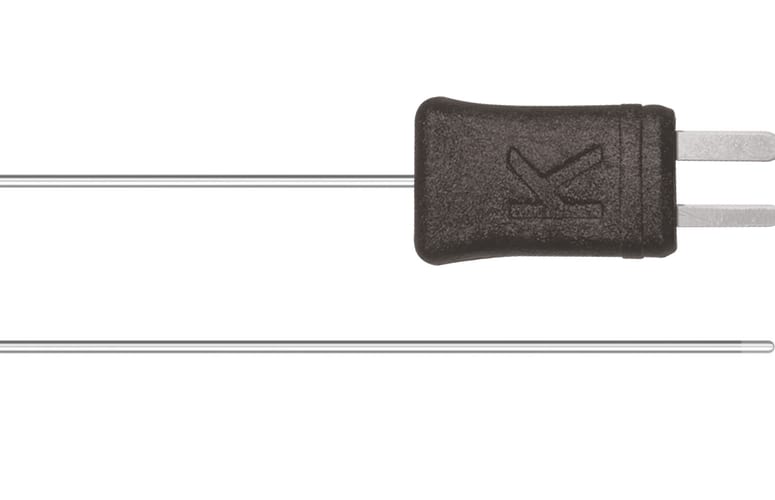

You will need at least one temperature sensor to use your logger. There is a wide selection of thermocouple sensors ranging from type K, T or J sensors to air, surface or probe sensors available.

Technical features and benefits in the field

The logger’s display provides you with a wide range of valuable information including current measurement values, threshold values, points where these thresholds have been exceeded, min/max values as well as the remaining battery power. And because all these values can be read off directly from the display, there is no need for you to boot up your PC. In addition to this nice little detail, the logger also has a super size memory and an exceptionally long battery life of up to 8 years. This gives you the freedom to read out the logger data at longer intervals, even when measuring cycles are shorter.

The testo 176 T4 data logger is IP 65 protected and can therefore also be used in dusty and dirty work environments. The standard AA batteries can be replaced by the user.

Possible areas of application

- Checking the temperature in ultra-low temperature freezers or under cryo conditions

- Measuring and logging flow and return temperatures at underfloor heating distributors in order to check that they are working properly

- Checking process temperatures

- Checking flow and return temperatures of heating systems

Programming and analyzing your data logger

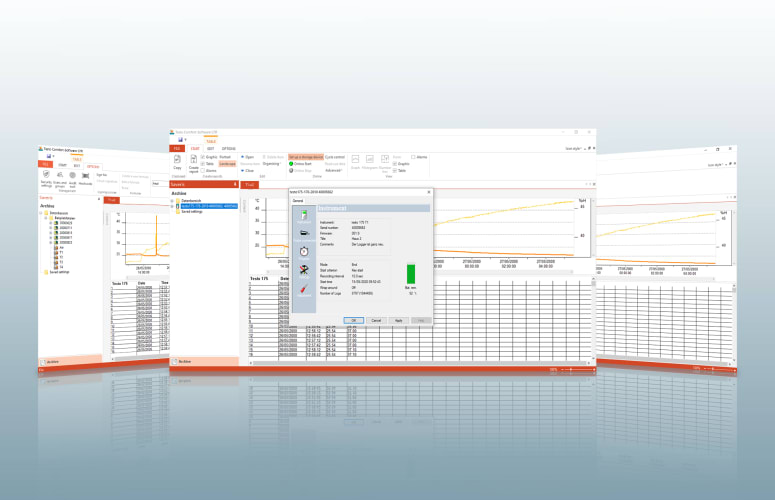

Choose one of three software versions to program or read out your logger or to analyze the measuring data you have obtained on your PC:

- Software ComSoft Basic – available for free downloading – allows you to program your logger and analyze the data quickly and easily

- Software ComSoft Professional – optional – provides you with additional possibilities and a more detailed analysis of the temperature values

- Software ComSoft CFR 21 Part 11 – optional – ideal for the special demands of the pharmaceutical sector in compliance with 21 CFR Part 11

You will need a USB cable (not included) to program your data logger. The data can be transferred to your PC either via USB cable or SD card. Both are available as accessories which can be ordered together with your testo 176 T4.

testo 176 T4 temperature data logger with external sensor ports (TC type T, K and J), wall mount, lock, battery, calibration protocol.